Brewery Vessels

by Greg Nachtegaele, Armstrong Crane & Rigging

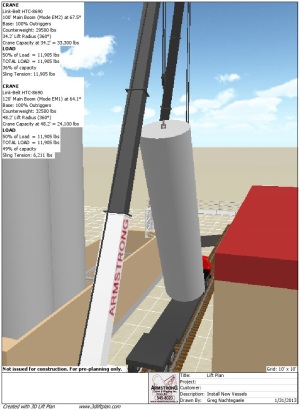

This is the lift plan for a very detailed installation of 3 vessels for a local brewery that took place in British Columbia, Canada.

There were many challenges to overcome during the planning of this lift.

First, a busy railroad system runs through the property of the brewery.

The most effective location for lifting was from an alley way of a busy trackline.

An alternate lifting area would have required a much larger crane and greater costs to the customer.

The initial planning had to be done with the schedule of trains through this system and with a track engineer on site at all times.

Second, the brewery was already established and this was going to be an expansion onto their property.

There was already walkways and piping previously established that constrained the lifting area.

Third, we were directly involved in the logistics since the vessels were coming from Germany.

The vessels had to be temporarily stored in an adjacent area.

We had to arrange how a truck would bring the tanks to the cranes and in what orientation.

Finally, the alley on the trackline was going to need to be protected for the crane to setup and what was going to be best for the install.

This alley was only 32' wide, so the tailswing of the primary crane had to be kept clear.

As well, there were also pedestrian and vehicle traffic associated with the business situated in a busier part of town.

It was decided that a tandem lift using two of our Linkbelt HTC 8690 truck cranes would be best.

Using 3D Lift Plan, we could tell exactly where we needed the center pin of the primary crane to be for installation.

Placing the crane too close would not allow us to stand the vessels up in the lifting area, and too far would mean moving the crane multiple times.

Because of the exactness of the measurements and 3D Lift Plan we could situate the crane exactly where it needed to be to lift all 3 vessels from one spot.

The Lift Plan helped us to see boom clearance, swing clearance, and also how much boom would be needed for the best configuration for capacity charts.

This worked very well as we could see the load changing as it became vertical which is a crucial for an operator to consider.

Our customer thought that these were very impressive because of the detail and the simplicity of the drawings as compared to a 2D CAD drawing.

The cost effectiveness and the safety of the lift, despite the time and logistics considerations, left our customer extremely happy with our plan.

I have used 3D Lift Plan numerous times and have some customers remarking that they have sent the drawings to their head office for such a detailed lift.

3D Lift Plan is by far the best program I have ever used for it's simplicity and ease of use.

Planned Lift vs Actual Lift