Downers Grove North High School

Brent Genseke, Area Erectors Inc.

In this lift plan we are setting a shop assembled truss over an existing/addition walkway,

inside a courtyard, on top of new steel. The truss dimensions are 15’-2” wide by 60’-8” long

and it weighed in at 4,527# not counting the block and rigging. This was not a heavy lift by

any means, but crane access, transportation of the truss to the site, and rotating the truss

once off loaded added some degrees of difficulty to the lift.

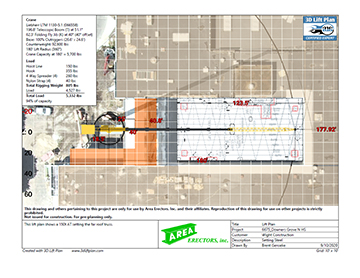

Crane placement on this project was limited due to underground hazards and the ability to keep

other trades working. On a prior site visit we were able to estimate a possible location and to

compile the dimensions needed i n order to generate an accurate representation of the jobsite

in 3D Lift Plan. Our crane vendor also brought a unique tool to the table, a drone. Using their

drone we were able to get a true birds eye view of the site as i t stood and import that image

into the lift plan. This gave the general contractor and the school district the ability to see

the current jobsite on the lift plan submitted. Between the images used, the documents generated,

and a site walk they could then easily make the correlation between the drawing and the site.

Starting off the lift, there was the difficulty in getting the shop assembled trusses to the site.

The jobsite is in the middle of a residential area and streets are narrow. Trying to navigate the

access for the semi and extended trailer while the truss was on the trailer took some precision

driving by the hauler. Patience, a couple of spotters, and a skilled driver and we were able to

overcome the logistics of getting the piece to the site. Once we had the piece within reach of the

crane we were able to really start the critical aspects of the lift.

The truss was fabricated and loaded on the truck upside down. So once the truss was on site we had

to offload the truss, stand it up, and then lay it over in order to rig it for setting. The

standing up and rolling over process was reviewed with the crane rental company and the operator

tasked with the job was on point. The truss rolled up and was laid over very smoothly and almost

effortlessly. Without quality operators and equipment, lifts like this are even more difficult.

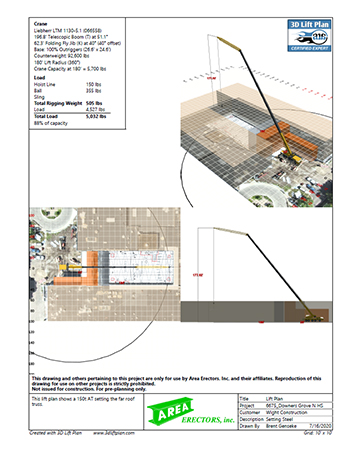

Truss stood up, rolled over, and now it is time to hoist. Prior to all that, we had to size the

crane. Looking at the access, the truss weight, and additional constraints we were trying to

thread a needle to make it all work. Through the planning process we were working with Nichols

Crane Rental out of Joliet IL. Nichols had been on the job a couple of times and were familiar

with access and restrictions to the site. The site had a strict no machinery before 8am rule due

to the residential area literally on the other side of the fence. Nichols was able to provide the

Liebherr LTM 1130 5.1 with jib to do the work. Outrigger placement, centerpin location, and tail

swing were all taken into account in order to get the crane set up in the exact location planned.

The crane was built in the precise location needed to uphold the accuracy of the lift plan.

Throughout the process 3D Lift Plan gave us the ability to bring as much information as

possible to the table. Crane capacity, crane l ocation, and the 3D ability to see clearances

all on a couple documents made the general contractor and school confident in our ability to

complete the work in a safe manner. The lift went off as planned and we were able to keep the

project on track. 3D Lift Planning the work, and working the 3D Lift Plan helped keep everything

on track. In closing, credit for the work in the end goes to the operators and ironworkers that

suit up each day to work safely.

At Area Erectors, we use 3D Lift Plan for a myriad of uses in planning our work. We will use it in

the planning stage to size a crane. We will use it once we have a job in order to layout crane

locations for different stages of construction. Lastly we use it once we have fabrication

drawings to finalize a lift plan and convey to our field team what we were looking at prior to

boots on the ground. This project i nvolved using 3D Lift Plan on multiple occasions where unique

situations were encountered.